Agriculture has a 10,000-year history, and it’s predominantly a history of technology. Developments from the plow and wheel to enclosures and the modern mechanical miracles of gas-powered tractors and sorters have consistently improved crop yields, allowing humanity to expand from tens of millions of people to a global population projected to top 10 billion this century.

When it comes to the next stages of that long course of innovation, vertical farming would seem to have all the right properties. Precise controls backed by data analysis can calibrate food quality, leading to further improvements in yields while reducing raw inputs like water. That’s critical at a time when the world’s climate is increasingly at a breaking point.

The energy efficiency of lamps or production systems can be improved, but not infinitely, so indoor crops will always be heavily dependent on electricity and other industrial support.

For Bowery Farming, no technology is too small to optimize, and no data is too insignificant to track. Combined together, the startup hopes to orchestrate the future of farming — and build a competitive moat in the process. To ultimately create a company of value, it needs to not just build differentiated technology but also build a brand with consumers, which we’ll turn to in the final part of this TC-1.

In parts one and two, I covered the history of vertical farming, Bowery’s origins and how it develops produce. In this third part, I’ll look at the company’s core tech infrastructure, explore how developments of just one component, LEDs, made vertical farming viable and investigate just how much climate savings Bowery can be expected to wring out as it grows in scale.

Lettux

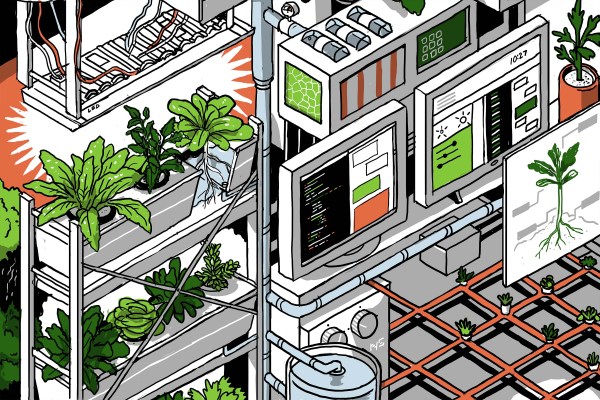

We can’t understand Bowery without describing BoweryOS. It’s the secret sauce that ties its automated systems, sensors and data collection together into a central nervous system. The company is tight-lipped about specifics but notes that it unlocks the ability to rapidly replicate its growth system at new farms.

“You could be the greatest farmer in the world in Salinas Valley, and I pick you up and bring you to New Jersey and that knowledge doesn’t transfer,” says Irving Fain, founder and CEO of Bowery Farming. “You put the Bowery operating system inside of that farm, and that farm now has the knowledge and understanding of every crop we’ve ever grown and every process we’ve ever run immediately available to it. In essence, what we’re really doing is building a distributed network of farms, whereby every new farm that enters that network benefits from the collective knowledge of the network that came before it.”